Melbourne Tram Museum

- Follow Melbourne Tram Museum on Twitter

- Follow Melbourne Tram Museum on Facebook

- Follow Melbourne Tram Museum on Instagram

- Follow Melbourne Tram Museum on Pinterest

- Follow Melbourne Tram Museum on Tumblr

- Subscribe to Melbourne Tram Museum's RSS feed

- Email Melbourne Tram Museum

Power collection for Melbourne tramcars

One of the major engineering problems in the early days of electric tramways was finding the best method to supply electric traction current to moving tramcars, as long extension cords were clearly not an option. The earliest electric tramways and railways [1] distributed power via use of either two- or three-rail systems, but this was hardly suitable for street tramways, due to the risk of electric shocks. Clearly something better was required.

Many attempts were made to use battery-electric tramcars based on the lead-acid battery, but these came unstuck due to the high weight of batteries, limited electric storage capacity and occasional emission of choking acid fumes from the batteries.

It was not until 1888 when Frank J. Sprague brought together the use of overhead wire and the sprung trolley pole with trolley wheel utilising the running rails as the earth return that the problem was solved. His tramway in Richmond, Virginia, became the model for most of the subsequent world-wide boom in electric tramways.

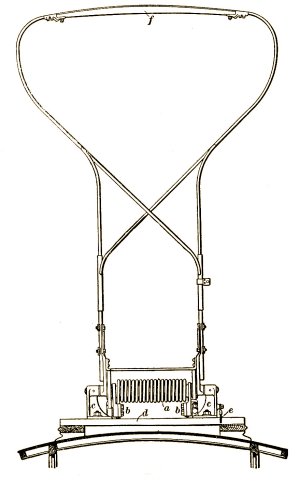

Diagram of bow collector.

Diagram of bow collector.- Source: ICS Reference Library.

However, Sprague’s success gave problems for the German firm of Siemens & Halske [2], as they did not wish to license the trolley pole technology. Instead, they pushed ahead with the alternative bow collector system, which came to be a feature of many continental European tramways. The bow collector was also used as the current collection method for the Hobart (Australia) tramway system, opened in 1893 based on technology supplied by Siemens. Bow collectors of various types were used exclusively by Hobart trams until the last line closed in 1960.

Some engineers looked to the precedent of cable tramways, and so the underground conduit power system was created. To the untrained eye, conduit track looked very similar to cable tram track, as there was a central slot between the rails that led down into a small tunnel. A device known as a plow, attached to the tramcar, ran along the conduit tunnel and maintained contact with the power cable within the tunnel.

Unfortunately, the capital cost of building underground conduit tunnels ruled out their use for all but the wealthiest cities, such as London, Paris, New York and Washington. In addition, significant maintenance was required in order to keep the conduit tunnel free of silt, mud and rubbish, adding to the cost of running a conduit tramway. However, the conduit tramways had an aesthetic advantage over overhead systems as they did not incur the clutter of overhead wires.

Before the conversion of Melbourne’s cable tramways to electric traction commenced, conversion of the cable tunnels for use as underground conduit was seriously considered, particularly for the Collins Street routes, but was ruled out on cost grounds as the tunnels would have required major modifications. Instead, conventional overhead wires were the chosen method for electrification of the cable routes.

The majority of the tramway systems in Australia used technology based on American practice, so when the NMETL and VR lines opened in Melbourne during 1906, it was a straightforward decision to use overhead wires with trolley poles fitted with trolley wheels for power collection.

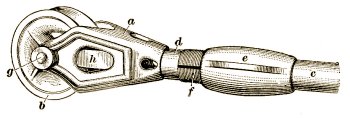

Diagram of trolley wheel.

Diagram of trolley wheel.- Source: ICS Reference Library.

Despite the simplicity of the trolley pole and wheel, they were not a perfect solution to the problem of current collection. The wheels were noisy, and resulted in significant amounts of wear to the overhead copper wire as a result of pitting caused through arcing from the wheel and mechanical wear. As the cost of copper climbed during the decades following World War I, M&MTB tramway engineers investigated alternatives to the trolley pole and wheel.

The M&MTB initiated an experiment in 1932 by converting all 15 tramcars [3] on the isolated Footscray system to use trolley shoes in place of trolley wheels. Each trolley shoe was equipped with a renewable insert of chilled cast iron which maintained contact with the overhead wire. Overseas experience showed that successful use of trolley shoes required lubrication of the overhead wire, so this was supplied by a graphite stick held in a ‘slicker’, which was attached to the trolley pole of a non-service tramcar, which was run over the lines on an ‘as required’ basis. This was generally set by the need to lubricate the overhead wire on curves, due to a greater degree of wear than on the straight, but it was found that lubrication on a weekly basis was usually sufficient.

In general, it was found that the Footscray overhead maintained a smooth and burnished surface with little wear on straight and large radius curved sections. Only on smaller radius curves was a higher level of mechanical wear noticed, and overall pitting of the wire was minimal. It was expected that this would lead to extended life for the overhead wire.

Previous experience had shown that more frequent shoe insert replacement was required if running trams with a mix of trolley wheels and shoes. This was attributed to the rougher surface of overhead wire as a result of pitting of the wire surface through arcing from the trolley wheels.

In 1931, three trams [4] were modified to use Fischer-type bow collectors and were used on the Holden Street shuttle service as an experiment. The bow collector plates required lubricating daily, and thorough cleaning and re-greasing on a weekly basis, using a mixture of yellow grease, tallow and engine oil.

| System | Overhead collection device |

Cost per

1000 miles |

Replacement interval (miles)

|

|---|---|---|---|

| M&MTB – main system | Trolley wheel |

12d

|

17,000

|

| M&MTB – Footscray | Trolley wheel |

7d

|

28,600

|

| M&MTB – Footscray | Trolley shoe |

7d

|

2,500

|

| M&MTB – Holden Street | Fischer bow collector |

23d

|

22,000

|

| Hobart | Fischer bow collector |

n.a.

|

45,000

|

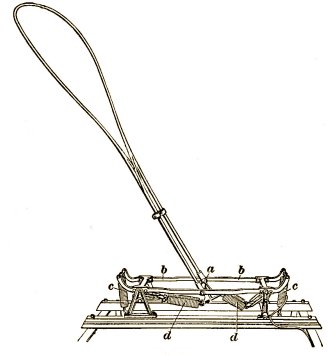

Unfortunately, trolley wheel equipped cars operated on the same routes, so the bow collectors had to cope with pitted and worn overhead wire, unlike the Hobart trams which were operated exclusively with bow collectors. It was thought that the difference in replacement intervals for the bow plates between the Holden Street and Hobart tramcars was due to the pitted overhead wire in Melbourne.

However, it was noted that wear on the Hobart bow plates was not evenly

spread across the bow plates, but concentrated in the centre of the

plate, often appearing as a distinct groove.

Diagram of reversible bow collector.

Diagram of reversible bow collector. - Source: ICS Reference Library.

Based on the comparative costs shown in the above table, use of Fischer bow collectors was not expanded, the equipment being removed from the subject tramcars in 1937-38. Use of the trolley shoes continued on the isolated Footscray system until 1940, when the M&MTB reverted back to trolley wheels for these lines. The wear reduction in overhead wire was seen to be a major benefit due to a combination of wire lubrication and use of trolley shoes.

The difference in replacement intervals for trolley wheels on the main M&MTB system and the Footscray lines was ascribed to the lower average speeds achieved on the Footscray lines.

The opening of the Bourke Street lines in 1955-56 saw the W6 and W7 class trams fitted with trolley shoe equipped poles, but with the iron insert of the previous shoes replaced by a graphite insert. This eliminated the need to lubricate the overhead wire with a slicker device, as now every tramcar lubricated the overhead. This initiative was such a success, both in terms of reduction in both overhead wire wear and noise levels, that by 1961 the entire system was converted to use trolley shoes fitted with graphite inserts.

However, increasing traffic levels during the 1970s saw the rise of accidents involving tram crews changing the trolley poles when shunting, particularly at intermediate crossovers. This was turning into a significant industrial issue with the union, so an investigation was carried out in 1977 into equipping W class tramcars with pantographs, as this would remove the need for tram crews to exit the tramcar when changing direction.

This exercise saw four different types of single arm pantographs fitted to W2 class tram 546, which was tested between Preston Workshops and the East and West Preston termini. Modifications to the overhead wiring between these locations were made to make it suitable for use with pantographs. One of these changes was to string the overhead in a slight zig-zag pattern in straight sections, to ensure that wear on the pantographs was not concentrated in a single point on the pantograph but spread more evenly.

Lubrication of the overhead wire was achieved by means of replaceable graphite strips mounted in the pantograph.

However, it was found that the wooden roof of the W2 class, and by extension the rest of the W class tramcar fleet, lacked sufficient strength to support the pantographs, which were significantly heavier than the trolley poles and bases they replaced.

The next step toward pantograph operation was made in 1984-85, when the two prototype B1 class articulated tramcars were delivered, being equipped with both trolley poles and pantographs from new. This was followed by the conversion of the Port Melbourne and St Kilda heavy rail lines to light rail operation in 1987, which were exclusively operated by pantograph-fitted A and B class tramcars. From this point on all new tramcars were fitted with pantographs from delivery.

From that point on, conversion of tramcars and the overhead from trolley pole to pantograph operation progressed steadily over the next two decades, the only holdout being the small number of remaining W class tramcars used for the City Circle and other tourist-oriented services. Eventually, even these were converted for pantograph operation when they were fitted with enhanced safety systems and track brakes, together with strengthened roofs.

The last trolley pole equipped Melbourne tramcar was restaurant car W2 442, which was retired from service in 2006, after almost 80 years of faithful service to the people of Melbourne.

W class trams fitted with pantographs in Spring Street, in front of

the Windsor Hotel.

W class trams fitted with pantographs in Spring Street, in front of

the Windsor Hotel.- Photograph courtesy Mal Rowe.

Footnotes

[1] The first practical electric railway locomotive was built by Ernst Werner von Siemens and demonstrated at the Berlin Industrial Exhibition of 1879.

[2] One of the founders of Siemens & Halske was Ernst Werner von Siemens.

[3] The Footscray tramcars converted to trolley shoes were of the X1 and X2 classes.

[4] U class trams 205, 209 and 211 were modified to use bow collectors, which were removed in 1937-38.

Bibliography

Buckley, R. J. (1975), History of Tramways from Horse to Rapid Transit,

David & Charles

Cooper, I. G. (1993), Hobart Tramways, A Centenary Commemoration

Review, Transit Australia Publishing

Cross, N., Budd, D., and Wilson, R. (1993) Destination City (Fifth

Edition), Transit Australia Publishing

ICS Reference Library (1923), Construction of Electric Tramways and

Railways, Unwin Brothers

M&MTB (1930) Melbourne & Metropolitan Tramways Board – Its Progress

and Development 1919-1929

Strickland, T. P. (1934), “Use of the Trolley Slide by the M&MTB”,

in Proceedings of the Australian & New Zealand Tramways Conference,

Fourth Conference Sydney March 1934